Can I autoclave it...? Essential guide to buying a lab autoclave

Can I autoclave it...? Essential guide to buying a lab autoclave

Choosing the right laboratory autoclave can be perplexing. From materials compatibility to safety features, here’s a handy guide for researchers asking, “Can I autoclave it…?”

🔬 What actually is a laboratory autoclave?

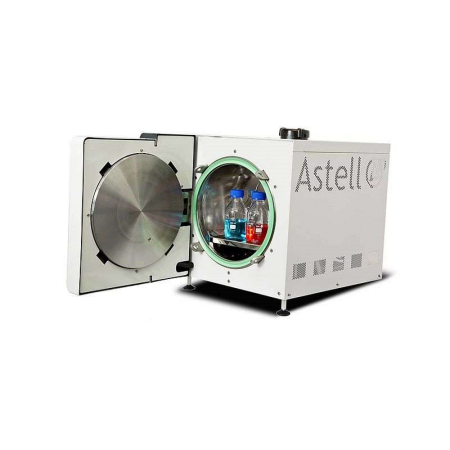

A lab autoclave uses high-pressure saturated steam to sterilise equipment—glassware, instruments, media, biohazardous waste—typically at ~121 °C and 15 psi. It’s indispensable across research labs, hospitals, vet clinics and pharma. Key for ensuring sterility, it eliminates bacteria, viruses, spores and fungi.

Can you autoclave it? Materials checklist

Not everything is suitable for autoclaving. Here's a quick rundown:

✅ Glassware: Borosilicate beakers, flasks—boil-proof and safe.

✅ Metals: Stainless steel tools and trays are fine.

⚠️ Plastics: Only autoclavable-grade (e.g. polypropylene) withstand heat. Avoid regular polystyrene.

❌ Oils, powders, volatile or reactive substances: These can degrade or spatter under steam .

📌 Tips: Leave bottle caps loose to prevent pressure build-up, use autoclave indicators, and never overload.

How does it work? A three-phase cycle

Most autoclaves (gravity or vacuum types) operate in three distinct stages:

1. Purge – steam displaces air.

2. Exposure – hold at sterilisation temperature/pressure.

3. Exhaust – controlled depressurisation.

Advanced models add vacuum drying, digital controls, safety locks, steam generators and cooling coils to speed cycles and enhance efficiency.

Types of lab autoclaves

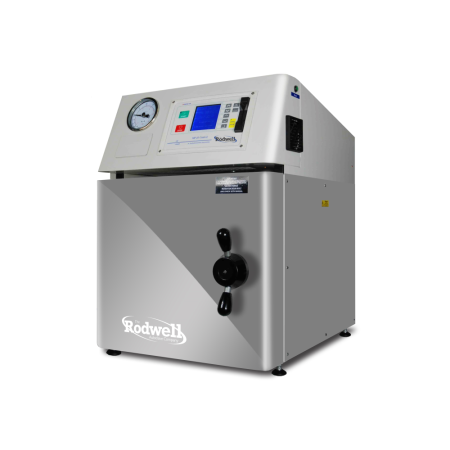

- Benchtop (N-type): Small, pressure-cooker style; affordable for beginners, simple media and tool sterilisation.

- Gravity displacement: Common in teaching labs; cost-effective and reliable.

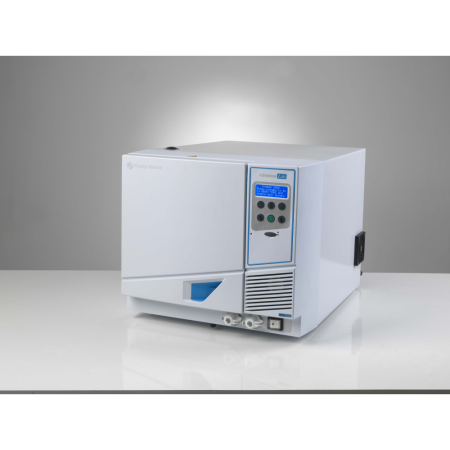

- Positive/Pre-vacuum (B-type): Remove air via vacuum before steam injection—better penetration for porous loads.

- Vacuum & drying (S-type): Top-tier units with vacuum-packed drying, ideal for scientific instruments.

What features should I look for?

Key Feature & Why it’s important

Chamber size - Match to typical workload—smaller units for basic use; larger (60–110 L) for core labs

Vacuum/pulse - Essential for sterilising wrapped, porous, or hollow items

Digital control - Touch screens, custom programs, safety locks, fault detection

Cooling/drying - Reduces cycle time, prevents condensation

Safety systems - Pressure relief valves, door interlocks, alarms

Validation & traceability - Cycle logging and printouts support lab compliance and audits

Buying considerations

1. Application: Sterilising simple media? A benchtop unit (35 L) may suffice. Frequent instrument use? Consider 60–110 L with vacuum functions.

2. Cost vs feature: Gravity units are budget-friendly; B/S-types cost more but offer higher performance.

3. Cycle time & water use: Features such as rapid cooling and vacuum drying save both time and resources.

4. Maintenance: Look for models with steam generators, filters, and accessible parts for ease of service.

5. Safety & compliance: Ensure CE/ASME approval and cycle documentation for QC purposes.

6. Utilities: Confirm power (230 V), water inlet (deionised/tap), compressed air and drain facilities.

FAQs: Quick answers

- Can I autoclave liquids? Yes—but use vented closures, don't overfill, and allow cooling time.

- Can I sterilise pipette tips? If using reusable tips, yes. For disposables, make sure they’re heat-resistant.

- What about waste? Use dedicated autoclavable biohazard bags; avoid metal bins.

Final thoughts

When asking “Can I autoclave it…?”, the answer often depends on the item’s heat resistance and material. Choose the right autoclave by balancing capacity, cycle speed, vacuum/drying ability, and safety. These features ensure spacer, efficient, and compliant operation—central to any successful lab.

Contact our sales team for further advice and help selecting the right unit

Product Category: Autoclaves

Manufacturer: Astell Scientific